Pretreatment

Our boiler pre-treatment programs are designed to decrease fuel consumption, avoid inefficiencies within your system and aid in the prevention of built-up scale and corrosion.

Steam Boilers

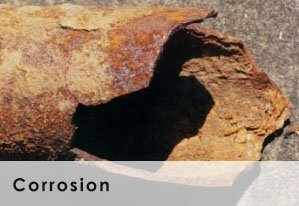

There are three main facets concerning the treatment of steam boilers: Corrosion, Scaling or sludging, and Energy efficiency.

Cooling Towers & Evaporative Condensers

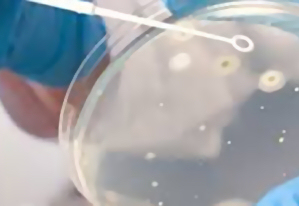

There are four main areas of concern for the treatment of cooling towers: Corrosion, Scaling, Biological control, and Energy efficiency.

Legionella Protocol

As per Industry Best Practices we follow ASHRAE 188P/ 12-200 Guideline Protocal for Legionella Control in Cooling Tower Systems.

Closed Loop & Heating Systems

There are three main facets concerning the treatment of closed recirculating systems (hot water heating, chilled and glycol water systems): Corrosion, Biological control, and Energy efficiency.

Thermal Fluids

Provide wide range of thermal fluids including but not limited to: Full strength Propylene and Ethylene glycol, Inhibited glycol, and services including glycol analysis, glycol pump, feed systems, and glycol waste disposal.

New Construction

Experience in construction design and field commissioning of various water treatment systems programs and equipment. Work along side Engineering Consultants/Architects/Designers to ensure top quality systems.

Analytical Testing

In-field testing, Bacteria testing, Deposit analysis, Water analysis, Glycol testing, Legionella testing, and Domestic water sterilization testing.

Operating Training Programs

Training seminars provided upon request on the following: Best practices, Legionella protocol, Curent technologies.